Food contact gloves are crucial tools in maintaining the hygiene and safety of the food we consume. To guarantee that these gloves are of superior quality and genuinely safe for use, manufacturers must undergo rigorous testing based on international standards. This article outlines the testing procedures and certifications that our gloves have passed to ensure they meet the highest safety standards for food handling.

Safety Testing of Food Contact Gloves

- Testing with Various Food Types:

To guarantee the gloves’ compatibility with all food types, we test them with a range of food categories, including water-based, alcoholic, acidic, oily, and dry foods, ensuring their reliability in diverse environments. - Overall Migration Test:

This test determines whether any substances migrate from the glove material to the food. According to laboratory results conducted under ISO 17025 standards, no foreign substances were detected in food samples that came into contact with our gloves, ensuring their safety. - Specific Migration for Heavy Metals:

Our gloves undergo testing for up to 24 types of heavy metals. The results showed no detectable heavy metals, confirming that the gloves are free from heavy metal contamination and safe for food handling.

Certifications and Compliance

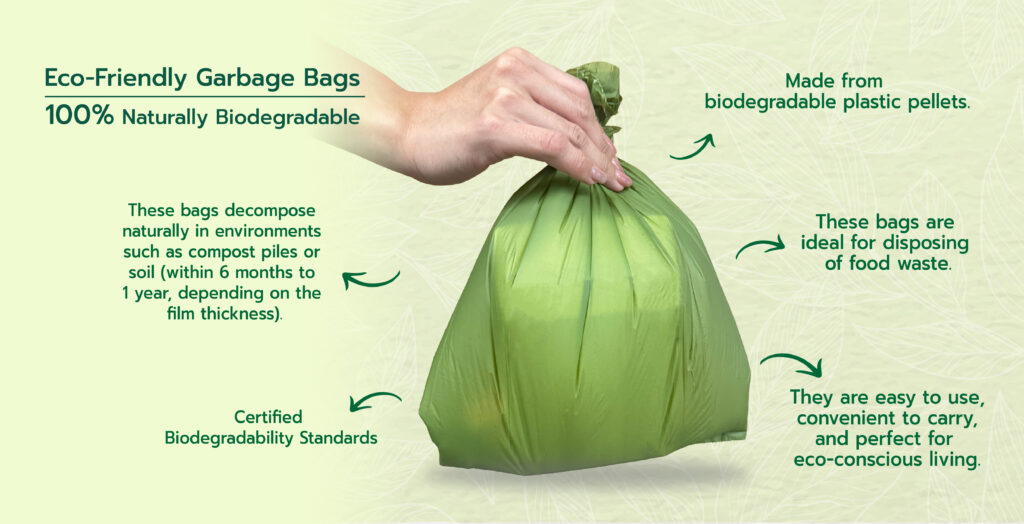

Bags and Gloves manufacturing processes are certified to international standards, including:

- ISO 9001:2015 (Quality Management Systems)

- ISO 14001:2015 (Environmental Management Systems)

These certifications validate our commitment to quality and sustainability.

Additionally, our production adheres to BRCGS standards for food safety, and we comply with Thai regulations for microbial detection to ensure safety at every stage of production.

Safe Raw Materials for Food Safety

We use food-contact tested plastic pellets in the production of our gloves, ensuring they are free from substances banned by international standards. This commitment to safe materials guarantees the quality and safety of every glove we manufacture, making them ideal for safe food handling.